E-mail : huayun@bdhyjx.com

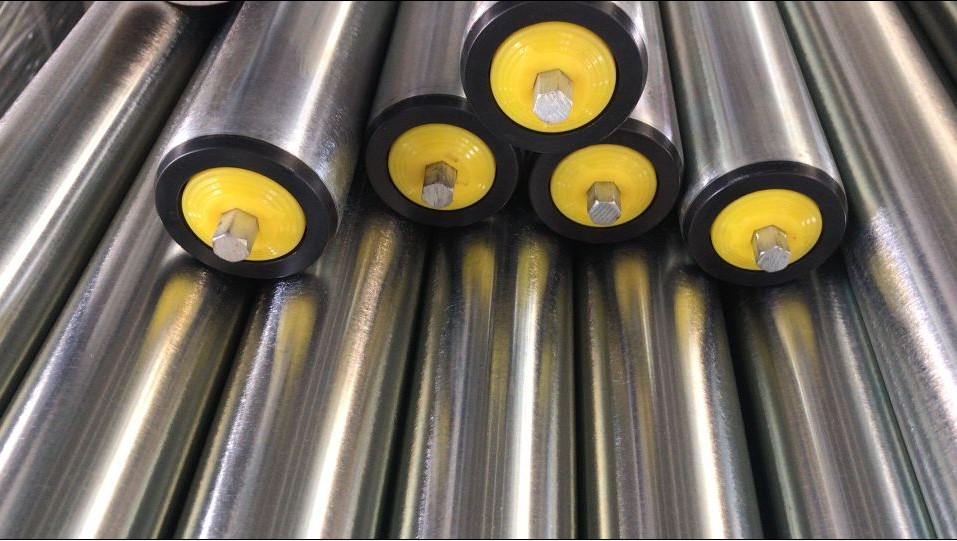

Gravity Roller

What is a gravity roller?

A gravity roller conveyor lets a product move on rollers using the force of gravity to move the load. Gravity conveyors are one of the simplest and affordable types of material handling systems. They work by allowing the product to roll along the upper surface.

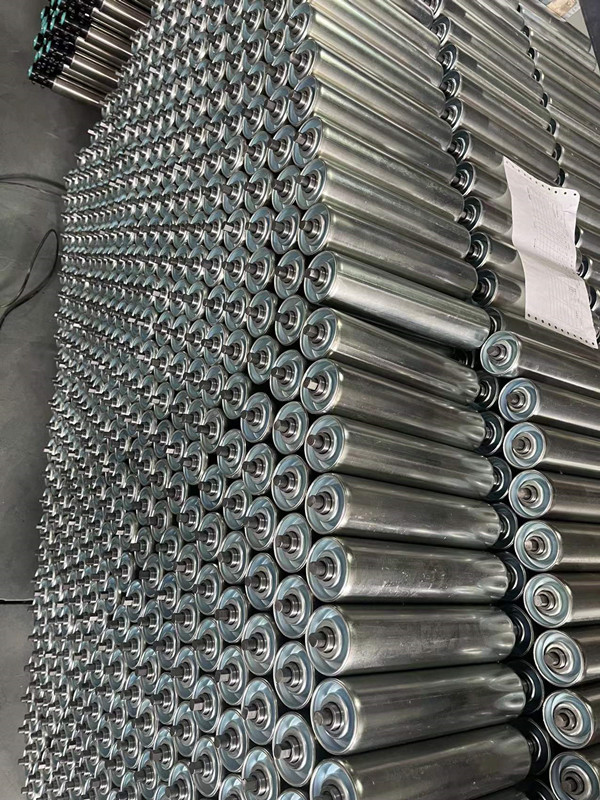

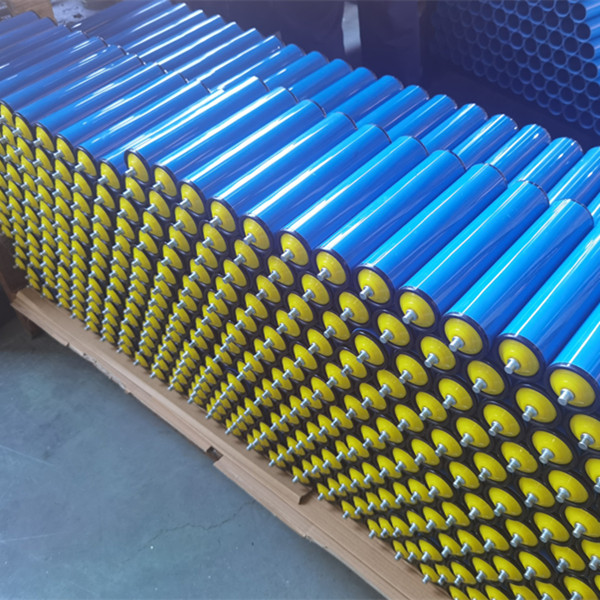

Gravity roller conveyors are some of the most commonly used conveyors in factories and other industrial settings. They offer a simple, reliable, inexpensive solution for transporting parts, products, and packages.

Shaft Z/P, Tube SS304 Roller Conveyor Slot 2

A gravity conveyor moves a product by taking advantage of the natural force of gravity. The product sits on rollers mounted on a slight decline to use gravity to assist forward motion and minimize frictional resistance. This system uses less energy than other conveyors, making it an ideal choice for certain labor-intensive applications.

Gravity Roller Conveyor. This is the most common type. It has no motors.

Gravity Conveyor Belt. Many people use this term for roller conveyors. But they have no belt.

Powered Roller Conveyor. These systems have rollers powered by a motor. There are two main styles, motor-driven roller conveyors and chain-driven live rollers.

Belt-driven roller conveyor is another alternative where a belt drives the rollers. These types of conveyors are more common for curves.

Line-shaft roller conveyor. Another variation of a belt-driven roller conveyor.

Heavy Duty Roller Conveyors. These generally refer to roller conveyors that have roller diameters of 2.5″, 3.5″ or larger. They are not very common as. Generally, conveyors for heavy loads have motors.

STEP-BY-STEP GUIDE TO CHOOSING THE RIGHT ROLLER CONVEYOR

Follow this simple process to help you choose the correct model conveyor:

Choose the width of the conveyor you need based on the product dimensions. Allow at least 1 inch on each side for clearance. Consider wider widths or side guides if the product can slide sideways.

Decide on the length of the roller table you need. Lengths of 5 or 10 feet can easily connect. Add curved sections to achieve the layout required.

Check the load rating table that shows the load capacity of each roller. Use light duty 1.5″ rollers for product loads under 100 pounds. Use medium-duty 1.9″ rollers and frames for loads over 100 pounds. Heavy-duty conveyors using 2.5″, 2-9/16″ and 3.5″ rollers are available for extremely heavy-duty loads.

Choose support centers for the conveyor's legs, if required. Provide support at 5, 8, or 10-foot intervals for all loads.

Copyright © Baoding Huayun Conveyor Machinery Co., Ltd. All Rights Reserved | Sitemap |